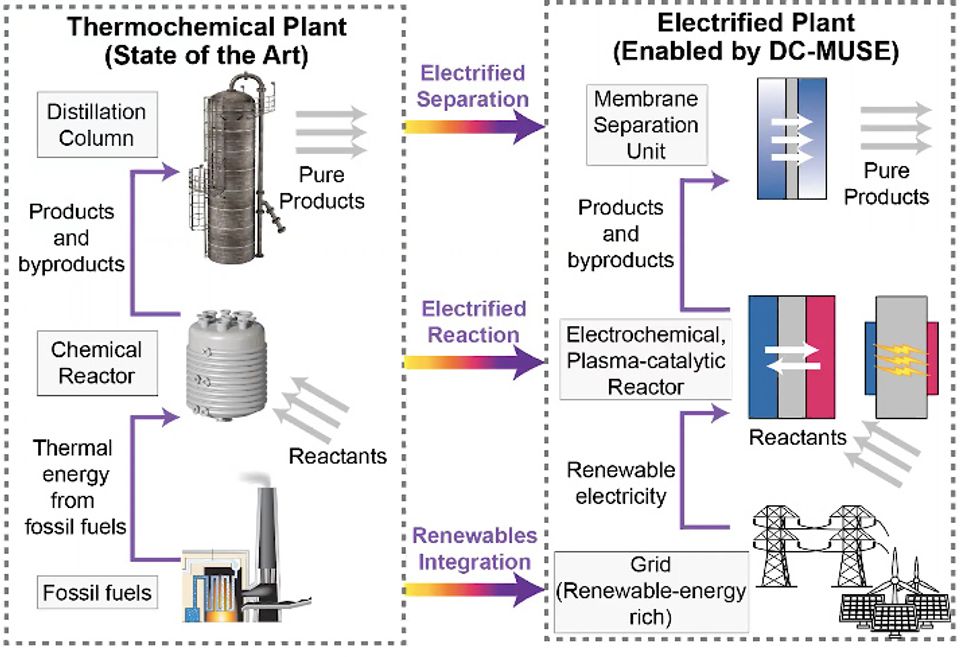

DC-MUSE was conceived this summer season in a workshop attended by over 40 firms and establishments, and arranged by a planning grant from the Nationwide Science Basis to construct capability in convergent analysis. Its intention is to develop applied sciences and techniques to assist the US chemical business migrate from thermal-based manufacturing processes to electricity-based ones.

A spread of presidency rules aimed toward reaching zero-carbon emissions are driving this migration. These greenhouse emissions rules will progressively come into impact within the coming many years, culminating, for instance, within the European Union’s intention to cut back 95 p.c of 1990 degree greenhouse emissions by 2050. These and different worldwide rules on greenhouse emissions may threaten as much as 12 p.c of all US exports ($220 billion), if the US chemical business shouldn’t be capable of decarbonize its processes. The duty is clearly huge, not only for the business itself however for the bigger economic system.

Andre TaylorNYU Tandon College of Engineering

Andre TaylorNYU Tandon College of Engineering

“Thirty p.c of US industrial CO2 emissions comes from the chemical business, and 93% of the chemical processes use fossil gasoline warmth,” famous Andre Taylor, affiliate professor on the NYU Tandon College of Engineering. “We’re speaking about altering a complete business that additionally entails an enormous societal impression, encompassing 70,000 merchandise, and 25% of the US gross home product.”

Many consultants imagine that step one in overhauling the chemical business will contain transferring away from thermally-driven chemical reactions and separation processes that require warmth from fossil fuels and transferring in the direction of reactions that use electrical energy generated by renewable assets, like wind and photo voltaic.

Whereas this migration has already began to happen, with penetration of renewable sources into the US electrical grid doubling prior to now decade, the applied sciences for integrating these sources into cost-effective electrified chemical processes has remained virtually non-existent.

Yury DvorkinNYU Tandon College of Engineering

Yury DvorkinNYU Tandon College of Engineering

“After assembly with many chemical business representatives, we discovered that applied sciences that might allow electrification on the commercial scale do not exist right now,” mentioned Yury Dvorkin, assistant professor at NYU’s Tandon College of Engineering. “The business wants help to develop these applied sciences to allow them to be adopted in a manner that is economically possible.”

One of many areas that Dvorkin and his colleagues believed they wanted to deal with was overcoming rising reliability points that inhibit and improve the price of utilizing renewable vitality within the electrical grid. In different phrases, how do you make sure that there aren’t any provide interruptions to the supply of electrical energy when vitality from the solar and wind might be intermittent?

In the mean time, vitality storage applied sciences will not be fully as much as the duty of balancing out the intermittency of renewable electrical energy. Consequently, NYU Tandon researchers have been taking a look at storing vitality within the type of chemical bonds, versus electrons, as a potential resolution.

In vitality storage approaches like this, vitality is saved chemically within the type of hydrogen, and that hydrogen is reused later in a gasoline cell. The gasoline cells used to seize the vitality are known as redox-flow batteries (RFBs). RFBs include a constructive and unfavourable electrolyte saved in two separate tanks. When the liquids are pumped into the battery cell stack located between the tanks, a redox response happens and generates electrical energy on the battery’s electrodes.

A number of NYU researchers not too long ago revealed a paper within the journal Cell Experiences Bodily Science that appears at enhancing the vitality storage capabilities and economics of those RFBs.

The NYU researchers did not merely tweak RFB know-how to enhance its vitality density or scale back their prices. As a substitute of simply plugging RFBs into renewable vitality sources to retailer their intermittent vitality manufacturing, the NYU researchers demonstrated how you can use RFB ideas to utterly combine chemical manufacturing into the entire vitality storage course of.

Miguel ModestinoNYU Tandon College of Engineering

Miguel ModestinoNYU Tandon College of Engineering

“In precept, you may think about chemical vegetation appearing as vitality storage reservoirs, however on the similar time producing chemical merchandise,” defined Miguel Modestino, an assistant professor at NYU, and one of many co-authors of the Cell Experiences paper. “The storage worth it gives lowers the associated fee for the manufacturing of the chemical that you just wish to make on the finish of the day.”

Modestino added that this strategy additionally permits the chemical firms to combine fluctuating sources of electrical energy, like renewables. You may thus decarbonize the business in a manner that’s each financial and features properly with the dynamics of a renewable-driven grid.

The DC-MUSE challenge has expanded dramatically since its concepts first took root a couple of months in the past. The challenge has already put collectively a gaggle of 30 investigators from 11 universities and three Nationwide Laboratories that cowl a large spectrum of analysis areas.

At NYU Tandon, Ryan Hartman, affiliate professor, is main a gaggle to develop plasma catalysis know-how for these kinds of chemical reactions. Taylor’s and Modestino’s teams are engaged on electrochemical reactors for chemical manufacturing. And Dvorkin has been engaged on integrating these vegetation inside the grid. Different teams exterior of NYU are investigating utilizing membranes for separations and system integration.

As well as, the NYU crew has been consulting with school on the regulation faculty and the enterprise faculty on find out how to design insurance policies that may allow the financial transition in the direction of renewable energy-driven chemical manufacturing.

The researchers are additionally reaching out to business to get early involvement. In actual fact, the genesis of the DC-MUSE challenge was a workshop by which NYU invited 50 business consultants and folks from academia to return collectively to speak in regards to the challenges within the chemical business, corresponding to course of intensification.

DC-MUSEMiguel Modestino

DC-MUSEMiguel Modestino

“We’ve got been speaking with folks within the large chemical manufacturing firms, who’ve began to develop pilots for electrified chemical manufacturing,” mentioned Elizabeth Biddinger, Metropolis Faculty of New York. Biddinger and Modestino not too long ago revealed an article in ECS Interfacesdescribing how environmental benefits of electro-organic syntheses corresponding to minimizing waste era, using non-fossil feedstocks, and on-demand chemical manufacturing are additionally massive drivers for sustainability in chemical processes throughout a number of sectors.

The involvement of petrochemical firms shouldn’t be accidentally. Petrochemical processes—and really a really small subset of petrochemical processes—account for greater than 80 p.c of the vitality and CO2 emissions from chemical processes, in accordance with Modestino.

Because the DC-MUSE picks up momentum, its architects at NYU envision the challenge as a go-to Heart for the basic engineering analysis that’s wanted to allow these applied sciences. Stated Modestino, “The way in which that we see it’s that you just do the analysis within the lab, you develop with lab-scale demonstrations, however then by means of partnerships with the businesses you may develop them into processes.”

Whereas the DC-MUSE challenge awaits its expanded intention although elevated funding, it’s already having an impression on the pedagogical strategy of the NYU professors.

“We have already got had discussions about joint Ph.D. positions so {that a} scholar can have a number of advisors,” mentioned Dvorkin. “On this manner, we are able to actually work collectively on these issues and supply college students with a multidisciplinary perspective, as a result of with out this kind of collaboration, with out this enter delivered to the scholars, there isn’t any solution to clear up societal issues.”

Taylor added: “From the purposes we have seen into our program, we all know that individuals wish to pursue issues that really have an effect on altering society and enhancing the world. Folks wish to uncover one thing elementary, but when it has a broader societal impression, folks can see its significance. For this reason I do analysis on this space.”

To be taught extra about initiatives which might be happening at NYU’s Tandon College of Engineering, please go to its web site.