For some firms, 2022 has been a promising yr. After the worldwide pandemic, the machining and manufacturing trade has slowly gained momentum, which has meant an excellent outlook for 2023.

For different firms, this previous yr has been tough. However now’s a time to pause and replicate on how one can thrive over the subsequent few years.

If you wish to keep forward of the competitors, you might want to perceive the forces that can have an effect on your trade over the 12 months. With this data, you then have to arrange methods that can assist you succeed.

What are you able to anticipate from the machining and manufacturing trade in 2023?

Listed below are a few of the developments, applied sciences, and points that it’s best to find out about…

What forces will form the machining trade in 2023

In 2023, a number of of the forces that can form the machining trade are the identical ones we’ve already skilled over the previous few years.

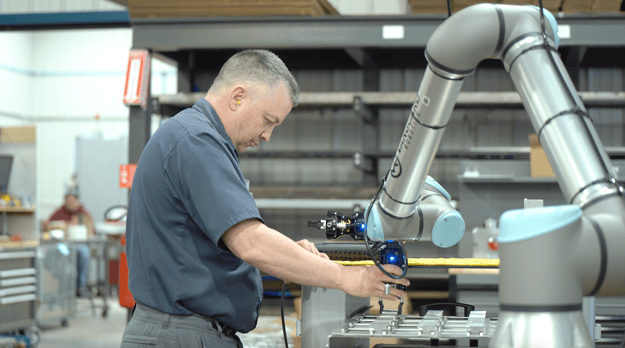

For instance, the “digital transformation” continues to have an effect on manufacturing. As digital applied sciences change into more and more extra accessible, there are much more methods to include them into our companies. With the rise of collaborative robotic utility kits, for instance, much more firms can add robots to their processes than ever earlier than, even with out earlier robotics information.

Different key forces that can proceed to form the machining trade embrace abilities shortages, good factories, provide chain disruptions, and extra.

If you need your machining enterprise to thrive over the approaching yr, it helps to acknowledge how these forces would possibly have an effect on your particular enterprise.

5 manufacturing developments to be careful for in 2023

We will already see the developments which can be more likely to form the machining trade over the subsequent yr and past.

What particular developments are affecting the outlook of the machining trade most?

Listed below are 5 key developments to maintain your eye on:

1. Provide chain disruptions proceed

With varied worldwide conditions nonetheless inflicting international provide chain disruption, your machining firm wants to seek out methods to adapt. Methods like “reshoring,” native sourcing, and various provide chains have gotten more and more necessary.

Again in 2019, we famous that the “offshoring bubble” (the place firms moved all their operations to cheaper markets) hadn’t popped abruptly, however was progressively deflating. Increasingly more firms at the moment are seeing the reality on this, as they notice that robotic automation is safer than counting on an offshore provide chain that might simply collapse.

2. Outsourcing is rising

Regardless of the autumn in offshoring, robots and in-house manufacturing aren’t for everybody. Some firms are at present going the opposite approach and outsourcing extra of their manufacturing.

Sports activities gear producer Peloton, for instance, outsourced all of its manufacturing in 2022 and 48% of firms reported a rise in outsourced manufacturing.

When you provide different firms with machining providers, this pattern could possibly be helpful for you. However keep in mind that native outsourcing is much less dangerous than offshoring.

3. Digital manufacturing reaches a tipping level

We have seen digital manufacturing options change into more and more refined over the previous few years. This pattern is more likely to proceed in 2023.

Our go to to the Automatica 2022 commerce present this yr confirmed an excellent demand from clients for intuitive, built-in options that work out of the field. This pattern is increasing the variety of producers that may add automation to their processes.

4. Expertise administration methods are very important

We defined earlier this yr why labor shortages are shaking up the manufacturing everywhere in the world proper now.

As machining firms transfer from guide labor to extra automated expertise, there’s a great demand for personnel who can function robotic expertise. In keeping with a Deloitte trade report, expertise administration is among the most necessary considerations for manufacturing firms this yr.

5. Deal with waste discount

Sustainability has been a pattern within the manufacturing trade for years now. However the concentrate on social and environmental duty continues to extend in significance.

Waste discount is not only a query of environmental influence. If you’re in search of methods to make your machining firm extra environment friendly, lowering your waste is one technique to obtain that. By lowering your machining waste and scrap supplies, you scale back the price of manufacturing.

Why provide chain and expertise retention are high in 2023

If it’s a must to select only one or two developments, which must you concentrate on in 2023?

Of the listing above, in all probability probably the most related for many firms are provide chain disruptions and expertise retention.

In keeping with the Deloitte manufacturing outlook 2022, previously yr, 80% of firm executives have skilled damaging provide chain impacts and 90% consider these disruptions have elevated in frequency over the previous decade.

On the identical time, one third of executives stated that their strategic precedence for 2023 was to retain high-performing workers.

Machining and manufacturing firms are in search of dependable methods to climate the challenges brought on by provide chain disruptions and hold their greatest folks. They want methods which can be fast to implement, do not value an excessive amount of, and can create a major and measurable influence on the enterprise.

Find out how to get forward of the competitors (and keep forward)

What can your small business do to elegantly climate these storms over the subsequent yr?

Many firms are turning to robotics. Robotic automation can assist you to each reply to produce chain disruption and retain your expertise.

With robots, your small business might be extra sturdy to worldwide disruptions. As an alternative of counting on offshore labor, automation can assist you retain extra operations in-house.

Robotic automation may also present a technique to implement expertise upskilling, giving your workers extra of a motive to remain of their jobs. By coaching them to make use of robots, your workers achieve worthwhile abilities for his or her profession and so they can transfer to extra rewarding, higher-value actions.

We do not know for certain what the subsequent yr has in retailer for us…

However if you wish to keep forward of the curve in 2023, robotic automation is definitely a expertise price your consideration.

What developments do you suppose will dominate over the subsequent yr? Inform us within the feedback beneath or be a part of the dialogue on LinkedIn, Twitter, Fb, or the DoF skilled robotics neighborhood.