This sponsored article is delivered to you by COMSOL.

Historical past teaches that the Industrial Revolution started in England within the mid-18th century. Whereas that period of sooty foundries and mills is gone, manufacturing stays important — and difficult. One promising technique to meet fashionable industrial challenges is through the use of additive manufacturing (AM) processes, reminiscent of powder mattress fusion and different rising strategies. To satisfy its promise of fast, exact, and customizable manufacturing, AM calls for greater than only a retooling of manufacturing facility gear; it additionally calls for brand spanking new approaches to manufacturing facility operation and administration.

Determine 1. An 1873 illustration of coal mines and iron works in England’s West Midlands. As one of many world’s first industrialized areas, a part of this space turned generally known as “the Black Nation” for its soot-covered panorama.

Picture within the public area by way of Wikimedia Commons

That’s the reason Britain’s Manufacturing Know-how Centre (MTC) has enhanced its in-house metallic powder mattress fusion AM facility with a simulation mannequin and app to assist manufacturing facility employees make knowledgeable selections about its operation. The app, constructed utilizing the Software Builder within the COMSOL Multiphysics software program, exhibits the potential for pairing a full-scale AM manufacturing facility with a so-called “digital twin” of itself.

“The mannequin helps predict how warmth and humidity inside a powder mattress fusion manufacturing facility might have an effect on product high quality and employee security,” says Adam Holloway, a know-how supervisor throughout the MTC’s modeling staff. “When mixed with information feeds from our facility, the app helps us combine predictive modeling into day-to-day decision-making.” The MTC undertaking demonstrates the advantages of putting simulation instantly into the arms of right this moment’s industrial workforce and exhibits how simulation might assist form the way forward for manufacturing.

“We’re attempting to current the findings of some very advanced calculations in a simple-to-understand approach. By creating an app from our mannequin, we will empower employees to run predictive simulations on laptops throughout their every day shifts.”

—Adam Holloway, MTC Know-how Supervisor

Additive Manufacturing for Aerospace With DRAMA

To assist fashionable British factories hold tempo with the world, the MTC promotes high-value manufacturing all through the UK. The MTC relies within the historic English industrial metropolis of Coventry (Determine 2), however its focus is solely on the longer term. That’s the reason the staff has dedicated vital human and technical assets to its Nationwide Centre for Additive Manufacturing (NCAM).

Determine 2. The headquarters of the Manufacturing Know-how Centre in Coventry, England.

“Adopting AM isn’t just about putting in new gear. Our shoppers are additionally in search of assist with implementing the digital infrastructure that helps AM manufacturing facility operations,” says Holloway. “Together with enterprise software program and information connectivity, we’re exploring how you can embed simulation inside their techniques as effectively.”

The NCAM’s Digital Reconfigurable Additive Manufacturing for Aerospace (DRAMA) undertaking gives a priceless venue for this exploration. Developed in live performance with quite a few producers, the DRAMA initiative contains the brand new powder mattress fusion AM facility talked about beforehand. With that mini manufacturing facility as DRAMA’s stage, Holloway and his fellow simulation specialists play necessary roles in making its manufacturing of AM aerospace elements a hit.

Making Gentle Materials Add As much as Stable Objects

What makes a producing course of “additive”, and why are so many industries exploring AM strategies? Within the broadest sense, an additive course of is one the place objects are created by including materials layer by layer, somewhat than eradicating it or molding it. A reductive or subtractive course of for producing an element might, for instance, start with a stable block of metallic that’s then minimize, drilled, and floor into form. An additive methodology for making the identical half, in contrast, begins with empty area! Free or mushy materials is then added to that area (underneath fastidiously managed circumstances) till it kinds the specified form. That pliable materials should then be solidified right into a sturdy completed half.

Determine 3. An instance of an element produced by means of the metallic powder mattress fusion course of.

Totally different supplies demand totally different strategies for producing and solidifying additive kinds. For instance, frequent 3D printers offered to shoppers produce objects by unspooling heat plastic filament, which bonds to itself and turns into tougher because it cools. Against this, the metallic powder mattress fusion course of (Ref. 1) begins with, as its title suggests, a powdered metallic which is then melted by utilized warmth and re-solidified when it cools. A component produced by way of the metallic powder mattress fusion course of might be seen in Determine 3.

How Warmth and Humidity Have an effect on Steel Powder Mattress Fusion

“The market alternatives for AM strategies have been understood for a very long time, however there have been many obstacles to large-scale adoption,” Holloway says. “A few of these obstacles might be overcome through the design section of merchandise and AM amenities. Different points, such because the impression of environmental circumstances on AM manufacturing, should be addressed whereas the ability is working.”

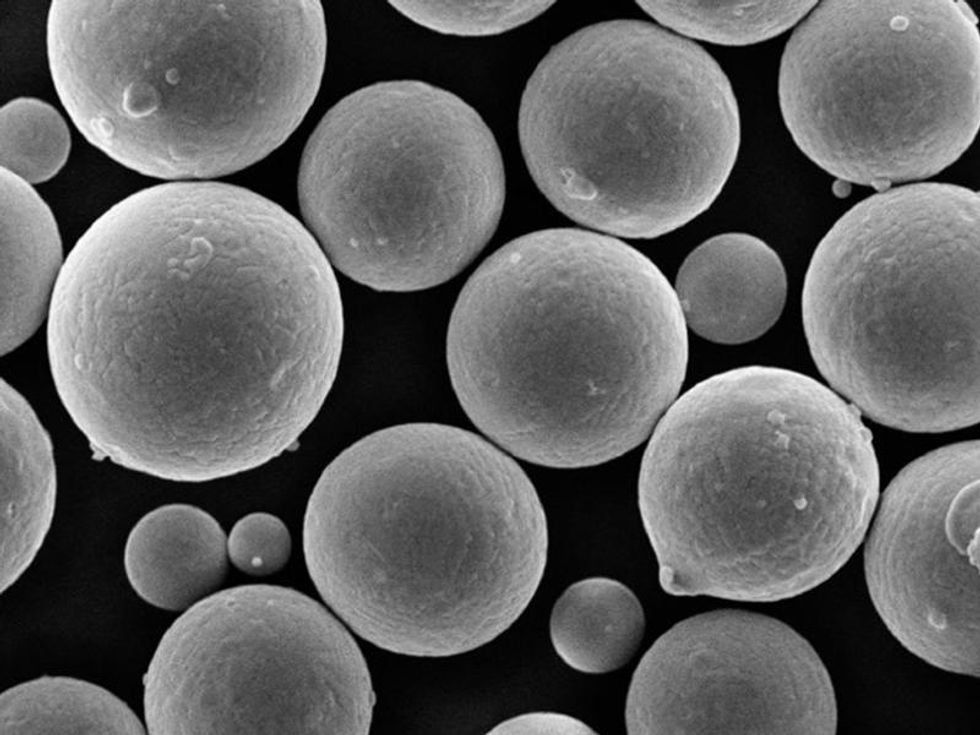

Determine 4. A microscopic close-up of powdered metallic grains, as used for powder mattress fusion.

As an example, sustaining cautious management of warmth and humidity is a vital job for the DRAMA staff. “The metallic powder used for the powder mattress fusion course of (Determine 4) is extremely delicate to exterior circumstances,” says Holloway. “This implies it will probably start to oxidize and choose up ambient moisture even whereas it sits in storage, and people processes will proceed because it strikes by means of the ability. Publicity to warmth and moisture will change the way it flows, the way it melts, the way it picks up an electrical cost, and the way it solidifies,” he says. “All of those components can have an effect on the ensuing high quality of the components you’re producing.”

Careless dealing with of powdered metallic isn’t just a risk to product high quality. It may threaten the well being and security of employees as effectively. “The metallic powder used for AM processes is flammable and poisonous, and because it dries out, it turns into much more flammable,” Holloway says. “We have to repeatedly measure and handle humidity ranges, in addition to how free powder propagates all through the ability.”

To take care of correct atmospheric circumstances, a producer might increase its manufacturing facility’s air flow with a full local weather management system, however that could possibly be prohibitively costly. The NCAM estimated that it will price practically half 1,000,000 English kilos so as to add local weather management to its comparatively modest facility. However what if they might adequately handle warmth and humidity with out including such an advanced system?

Responsive Course of Administration with Multiphysics Modeling

Maybe utilizing multiphysics simulation for cautious course of administration might present an economical various. “As a part of the DRAMA program, we created a mannequin of our facility utilizing the computational fluid dynamics (CFD) capabilities of the COMSOL software program. Our mannequin (Determine 5) makes use of the finite factor methodology to unravel partial differential equations describing warmth switch and fluid movement throughout the air area in our facility,” says Holloway. “This enabled us to check how environmental circumstances could be affected by a number of variables, from the climate exterior, to the variety of machines working, to the way in which machines had been positioned contained in the store. A mannequin that accounts for these variables helps manufacturing facility employees modify air flow and manufacturing schedules to optimize circumstances,” he explains.

A Simulation App that Empowers Manufacturing unit Workers

The DRAMA staff made their mannequin extra accessible by constructing a simulation app of it with the Software Builder in COMSOL Multiphysics (Determine 6). “We’re attempting to current the findings of some very advanced calculations in a simple-to-understand approach,” Holloway explains. “By creating an app from our mannequin, we will empower employees to run predictive simulations on laptops throughout their every day shifts.”

The app consumer can outline related boundary circumstances for the start of a manufacturing facility shift after which make ongoing changes. Over the course of a shift, warmth and humidity ranges will inevitably fluctuate. Maybe manufacturing facility employees ought to alter the manufacturing schedule to take care of half high quality, or possibly they simply must open doorways and home windows to enhance air flow. Customers can change settings within the app to check the potential results of actions like these. For instance, Determine 8 presents isothermal floor plots that present the impact that opening the AM machines’ construct chambers has on air temperature, whereas Determine 9 exhibits how airflow is affected by opening the ability doorways.

A Step Towards a “Manufacturing unit-Degree Digital Twin”

Whereas the present app is a vital step ahead, it does nonetheless require employees to manually enter related information. Wanting forward, the DRAMA staff envisions one thing extra integral, and subsequently, extra highly effective: a “digital twin” for its AM facility. A digital twin, as described by Ed Fontes in a 2019 put up on the COMSOL Weblog (Ref. 2), is “a dynamic, repeatedly up to date illustration of an actual bodily product, system, or course of.” You will need to be aware that even probably the most detailed mannequin of a system isn’t essentially its digital twin.

“To make our manufacturing facility atmosphere mannequin a digital twin, we’d first present it with ongoing reside information from the precise manufacturing facility,” Holloway explains. “As soon as our manufacturing facility mannequin was working within the background, it might modify its forecasts in response to its information feeds and counsel particular actions based mostly on these forecasts.”

“We need to combine our predictive mannequin right into a suggestions loop that features the precise manufacturing facility and its employees. The objective is to have a holistic system that responds to present manufacturing facility circumstances, makes use of simulation to make predictions about future circumstances, and seamlessly makes self-optimizing changes based mostly on these predictions,” Holloway says. “Then we might really say we’ve constructed a digital twin for our manufacturing facility.”

Simulation at Work on the Manufacturing unit Flooring

As an intermediate step towards constructing a full factory-level digital twin, the DRAMA simulation app has already confirmed its price. “Our manufacturing companions might already see how modeling might help with planning an AM facility, however probably not perceive the way it might help with operation,” Holloway says. “We’re displaying the worth of enabling a line employee to open up the app, enter in just a few readings or import sensor information, after which shortly get a significant forecast of how a batch of powder will behave that day.”

Past its sensible insights for producers, the general undertaking might provide a broader lesson as effectively: By pairing its manufacturing line with a dynamic simulation mannequin, the DRAMA undertaking has made your complete operation safer, extra productive, and extra environment friendly. The DRAMA staff has achieved this by deploying the mannequin the place it will probably do probably the most good — into the arms of the individuals engaged on the manufacturing facility ground.