Subsequent, it is advisable be clear about what you want out of your automated SME welding answer. Your moveable robotic arm is a device and to make one of the best use of it, it is advisable know what you need it to do. Your automation technique ought to match your wider industrial and enterprise technique – akin to decreasing working prices over the long-term or rising output.

Carry out a threat evaluation

Whereas cobots don’t usually require the extra security options that conventional industrial robots do akin to security cages, they’re nonetheless machines and have to be handled with care. Our e-series of cobots include a spread of built-in security options, however it’s best to nonetheless contemplate the impression shifting components, sharp edges and welding torches may have in your office well being and security.

Choose your cobot

Our e-Collection cobots include a spread of most allowed payloads and reaches to be able to match your funding to what you are promoting wants. On the smaller finish of the size is the UR3e, which has a most payload of 3kg, a weight of 11.2kg, and a attain of 500mm. The UR20, alternatively, can handle as much as 20kg and has a attain of 1750mm.

Arrange your workspace

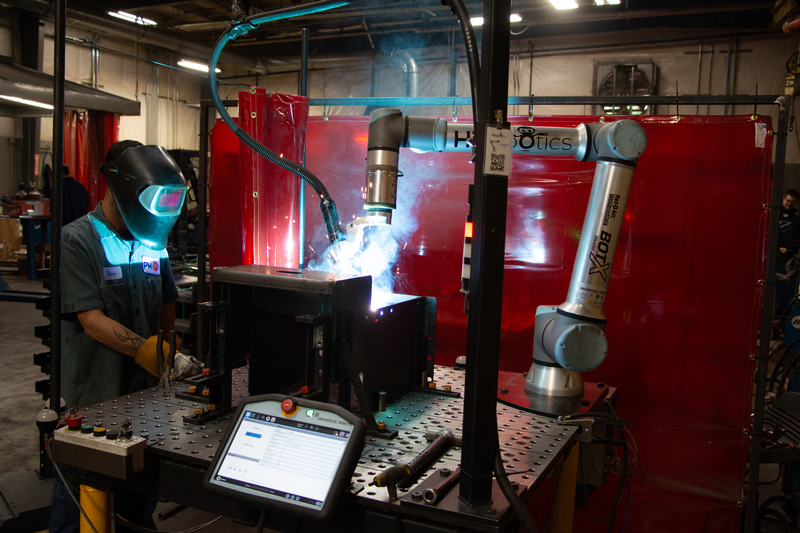

One of many main advantages of cobots, together with their flexibility, is how small their footprints are. When mixed with the truth that you usually received’t want the large-scale security cages and different security options related to conventional industrial robots, which means you may not must fully redesign your present workspace.

One other factor to contemplate is that your robotic work cell is probably going going to comprise of extra than simply your cobot arm and a desk. When you think about the total welding work cycle, you rapidly begin to see that extra parts could also be required. Listed here are some issues you might want to consider:

- the ability provide

- cables and provide traces for shielding gases

- multi-arm or linear axis for positioning

It’s important that you just all the time prioritize security. Automated welding purposes can have nice enterprise advantages, however they don’t actually eradicate any of the dangers related to guide welding. There may be nonetheless a threat – notably round fume publicity, weld spatter, proximity to different hazards and the torch itself.