Decrease supply prices

Sometimes, purchasers utilizing Common Robotic cobot obtain ROI on their collaborative robots in underneath a 12 months. That’s as a result of they’re comparatively easy to make use of and often require much less coaching and security infrastructure than conventional robots. And since they’ll improve throughput with out the necessity for added workers, cobots are value-generators somewhat than value facilities. MT Photo voltaic, for instance, was capable of meet a 300% seasonal improve in demand with out having to tackle any additional workers.

Enhanced office security

Cobot functions can contribute to a safer working atmosphere. Not solely do they free staff from having to carry out boring, soiled and doubtlessly harmful duties however the cobot itself comes with a spread of inbuilt security features.

What duties can a cobot do?

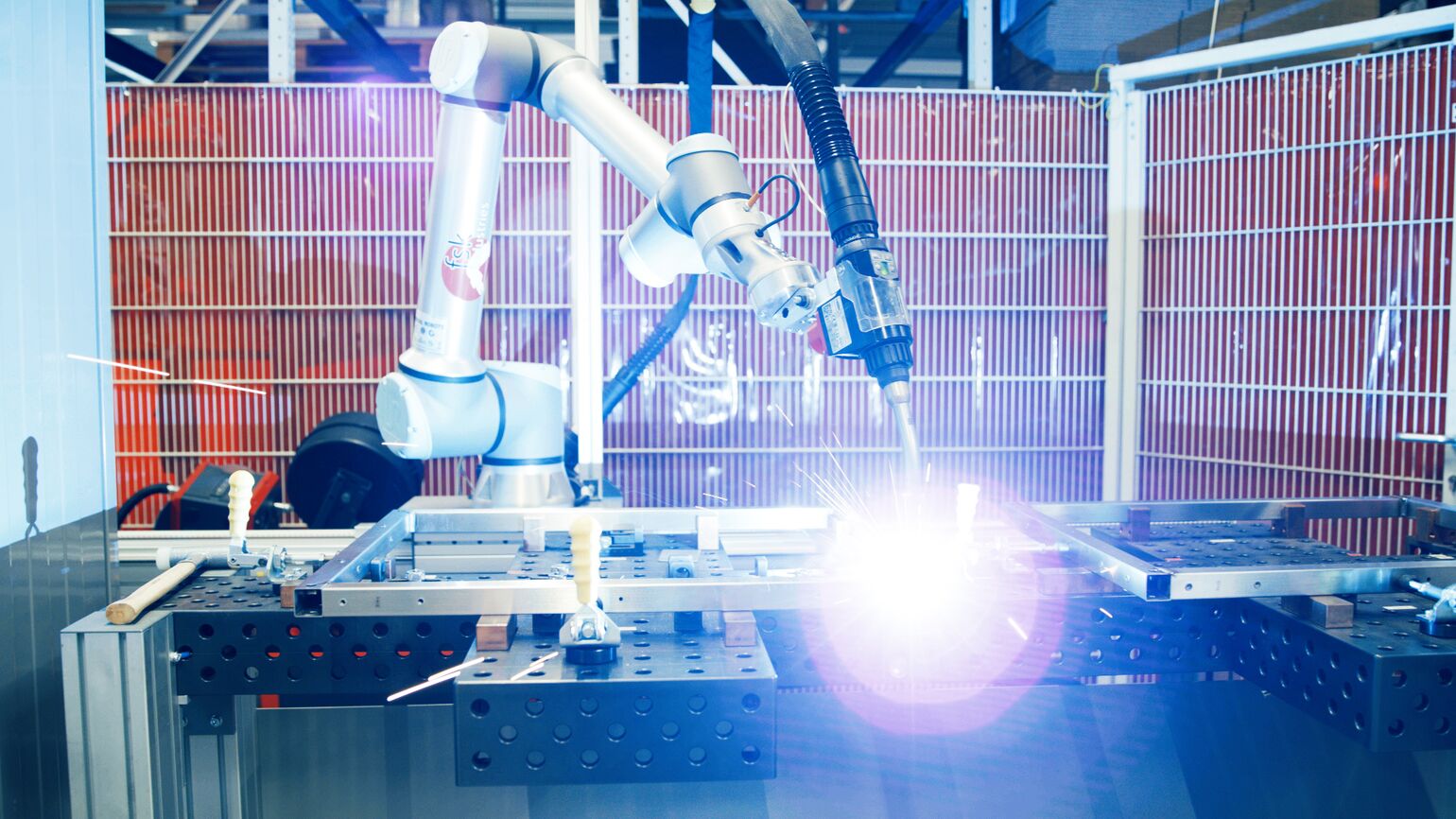

The excellent news is that relating to robotic welding, a cobot can do quite a bit. Our purchasers all around the world have used their cobots to carry out the next welding duties:

- Arc

- TIG

- Lazer

- MIG

- Ultrasonic

- Plasma

- Spot welding

One of many fundamental advantages of a cobot-based robotic welding utility is the pliability and relative ease of use when in comparison with different industrial robotics functions. With the appropriate software program options, finish effectors and utility kits from our UR+ ecosystem and a few minimal person coaching, skilled workers can get your cobot programmed toexecute all kinds of welding duties in as little as half-hour.

Cobots are additionally light-weight and have a smaller footprint than other forms of conventional robots. Which means it’s simpler to combine one into present workflows with out taking on an excessive amount of valuable floorspace. Regardless of cobots usually requiring much less security infrastructure, equivalent to cages, than different heavier-duty robots, an intensive security evaluation remains to be required earlier than implementation.

Getting began

When you even have your welding robotic arm, check out our extra in-depth information for establishing a welding utility.

Robotic welding and automating duties equivalent to soldering and brazing open up so many alternatives for companies of all sizes. They could be a highly effective software for these seeking to develop or an necessary approach of reducing working prices or lowering waste for these seeking to tighten up their operations. No matter your motivation, we’re right here to assist. Get in contact to get began at present.