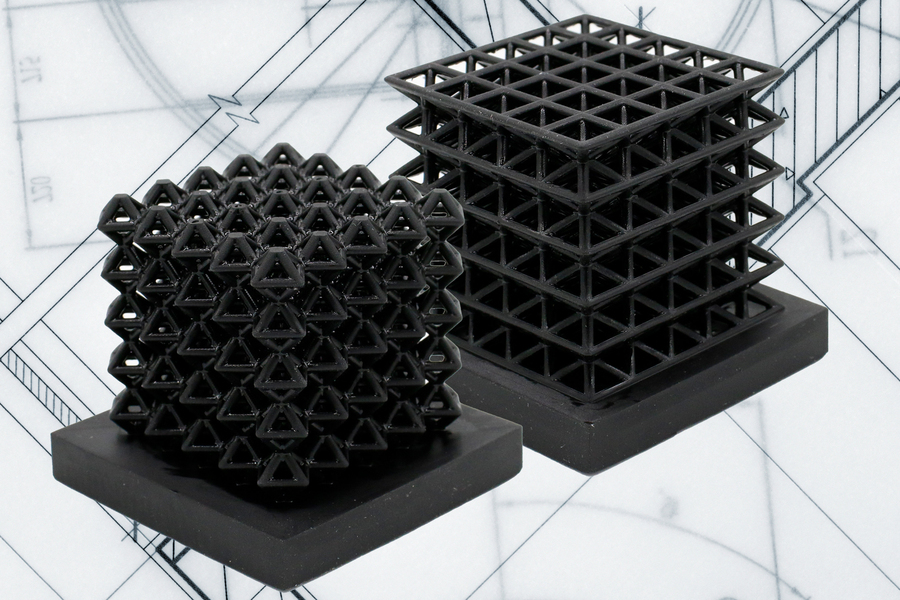

This picture reveals 3D-printed crystalline lattice constructions with air-filled channels, often called “fluidic sensors,” embedded into the constructions (the indents on the center of lattices are the outlet holes of the sensors.) These air channels let the researchers measure how a lot drive the lattices expertise when they’re compressed or flattened. Picture: Courtesy of the researchers, edited by MIT Information

By Adam Zewe | MIT Information Workplace

MIT researchers have developed a way for 3D printing supplies with tunable mechanical properties, that sense how they’re shifting and interacting with the surroundings. The researchers create these sensing constructions utilizing only one materials and a single run on a 3D printer.

To perform this, the researchers started with 3D-printed lattice supplies and included networks of air-filled channels into the construction in the course of the printing course of. By measuring how the strain adjustments inside these channels when the construction is squeezed, bent, or stretched, engineers can obtain suggestions on how the fabric is shifting.

The tactic opens alternatives for embedding sensors inside architected supplies, a category of supplies whose mechanical properties are programmed by way of type and composition. Controlling the geometry of options in architected supplies alters their mechanical properties, corresponding to stiffness or toughness. As an illustration, in mobile constructions just like the lattices the researchers print, a denser community of cells makes a stiffer construction.

This system might sometime be used to create versatile smooth robots with embedded sensors that allow the robots to know their posture and actions. It may also be used to supply wearable good gadgets that present suggestions on how an individual is shifting or interacting with their surroundings.

“The concept with this work is that we are able to take any materials that may be 3D-printed and have a easy solution to route channels all through it so we are able to get sensorization with construction. And in the event you use actually complicated supplies, then you’ll be able to have movement, notion, and construction multi function,” says co-lead creator Lillian Chin, a graduate scholar within the MIT Pc Science and Synthetic Intelligence Laboratory (CSAIL).

Becoming a member of Chin on the paper are co-lead creator Ryan Truby, a former CSAIL postdoc who’s now as assistant professor at Northwestern College; Annan Zhang, a CSAIL graduate scholar; and senior creator Daniela Rus, the Andrew and Erna Viterbi Professor of Electrical Engineering and Pc Science and director of CSAIL. The paper is revealed at this time in Science Advances.

Architected supplies

The researchers centered their efforts on lattices, a kind of “architected materials,” which displays customizable mechanical properties primarily based solely on its geometry. As an illustration, altering the scale or form of cells within the lattice makes the fabric roughly versatile.

Whereas architected supplies can exhibit distinctive properties, integrating sensors inside them is difficult given the supplies’ typically sparse, complicated shapes. Putting sensors on the skin of the fabric is often a less complicated technique than embedding sensors inside the materials. Nevertheless, when sensors are positioned on the skin, the suggestions they supply might not present a whole description of how the fabric is deforming or shifting.

As a substitute, the researchers used 3D printing to include air-filled channels instantly into the struts that type the lattice. When the construction is moved or squeezed, these channels deform and the quantity of air inside adjustments. The researchers can measure the corresponding change in strain with an off-the-shelf strain sensor, which supplies suggestions on how the fabric is deforming.

As a result of they’re included into the fabric, these “fluidic sensors” provide benefits over standard sensor supplies.

This picture reveals a smooth robotic finger made out of two cylinders comprised of a brand new class of supplies often called handed shearing auxetics (HSAs), which bend and rotate. Air-filled channels embedded inside the HSA construction hook up with strain sensors (pile of chips within the foreground), which actively measure the strain change of those “fluidic sensors.” Picture: Courtesy of the researchers

“Sensorizing” constructions

The researchers incorporate channels into the construction utilizing digital mild processing 3D printing. On this technique, the construction is drawn out of a pool of resin and hardened right into a exact form utilizing projected mild. A picture is projected onto the moist resin and areas struck by the sunshine are cured.

However as the method continues, the resin stays caught contained in the sensor channels. The researchers needed to take away extra resin earlier than it was cured, utilizing a mixture of pressurized air, vacuum, and complicated cleansing.

They used this course of to create a number of lattice constructions and demonstrated how the air-filled channels generated clear suggestions when the constructions had been squeezed and bent.

“Importantly, we solely use one materials to 3D print our sensorized constructions. We bypass the constraints of different multimaterial 3D printing and fabrication strategies which can be sometimes thought of for patterning comparable supplies,” says Truby.

Constructing off these outcomes, additionally they included sensors into a brand new class of supplies developed for motorized smooth robots often called handed shearing auxetics, or HSAs. HSAs could be twisted and stretched concurrently, which permits them for use as efficient smooth robotic actuators. However they’re troublesome to “sensorize” due to their complicated varieties.

They 3D printed an HSA smooth robotic able to a number of actions, together with bending, twisting, and elongating. They ran the robotic by way of a collection of actions for greater than 18 hours and used the sensor knowledge to coach a neural community that would precisely predict the robotic’s movement.

Chin was impressed by the outcomes — the fluidic sensors had been so correct she had issue distinguishing between the indicators the researchers despatched to the motors and the information that got here again from the sensors.

“Supplies scientists have been working exhausting to optimize architected supplies for performance. This looks like a easy, but actually highly effective thought to attach what these researchers have been doing with this realm of notion. As quickly as we add sensing, then roboticists like me can are available and use this as an lively materials, not only a passive one,” she says.

“Sensorizing smooth robots with steady skin-like sensors has been an open problem within the subject. This new technique supplies correct proprioceptive capabilities for smooth robots and opens the door for exploring the world by way of contact,” says Rus.

Sooner or later, the researchers expect to find new purposes for this system, corresponding to creating novel human-machine interfaces or smooth gadgets which have sensing capabilities inside the inside construction. Chin can also be fascinated about using machine studying to push the boundaries of tactile sensing for robotics.

“Using additive manufacturing for instantly constructing robots is engaging. It permits for the complexity I imagine is required for typically adaptive programs,” says Robert Shepherd, affiliate professor on the Sibley College of Mechanical and Aerospace Engineering at Cornell College, who was not concerned with this work. “Through the use of the identical 3D printing course of to construct the shape, mechanism, and sensing arrays, their course of will considerably contribute to researcher’s aiming to construct complicated robots merely.”

This analysis was supported, partly, by the Nationwide Science Basis, the Schmidt Science Fellows Program in partnership with the Rhodes Belief, an NSF Graduate Fellowship, and the Fannie and John Hertz Basis.

tags: c-Analysis-Innovation

MIT Information